Building the Adirondack Guideboat

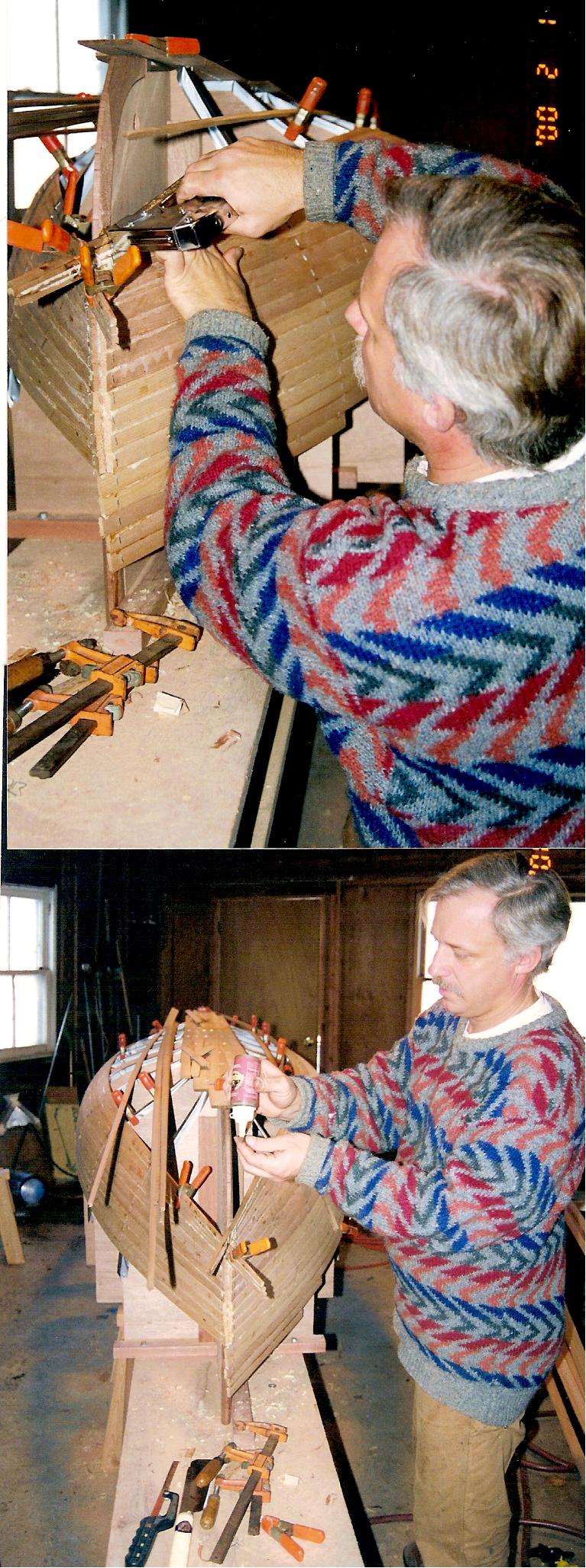

Building this Adirondack Guideboat started with a “strong back”; a straight wooden I-beam to put the molds on. With this platform, there is no shifting of the form during construction. Once the molds are fastened, the cedar strips can be stapled on, and then glued.

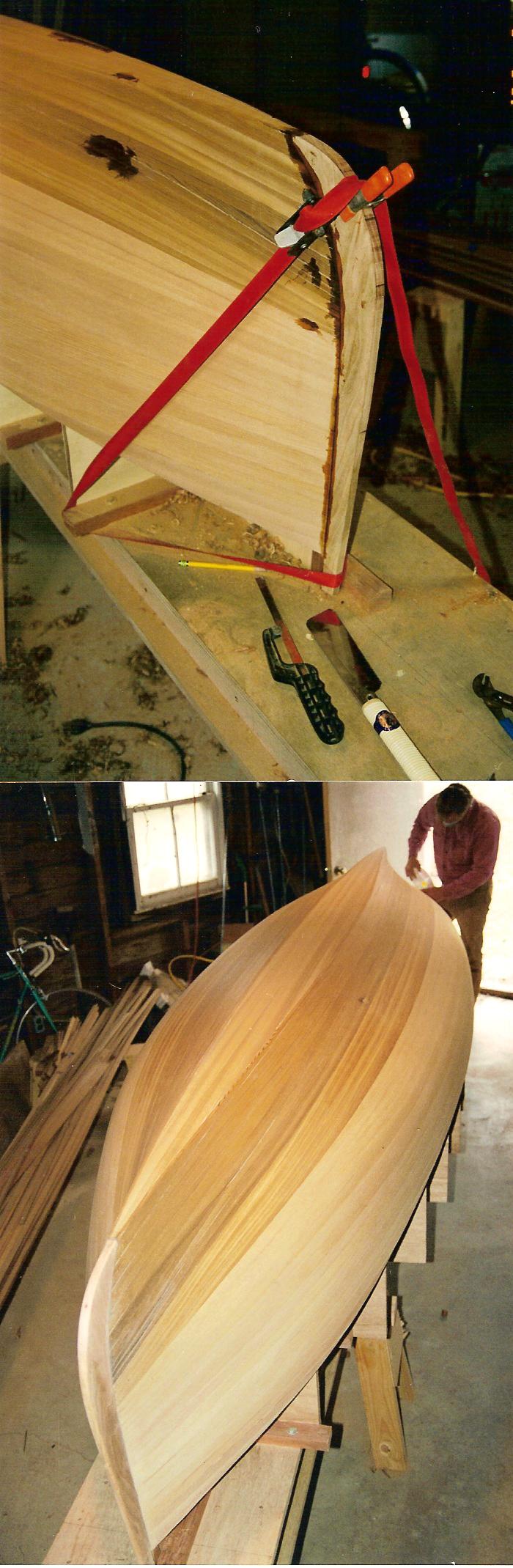

Once the outside of the hull has been sanded, the stems can be added on.

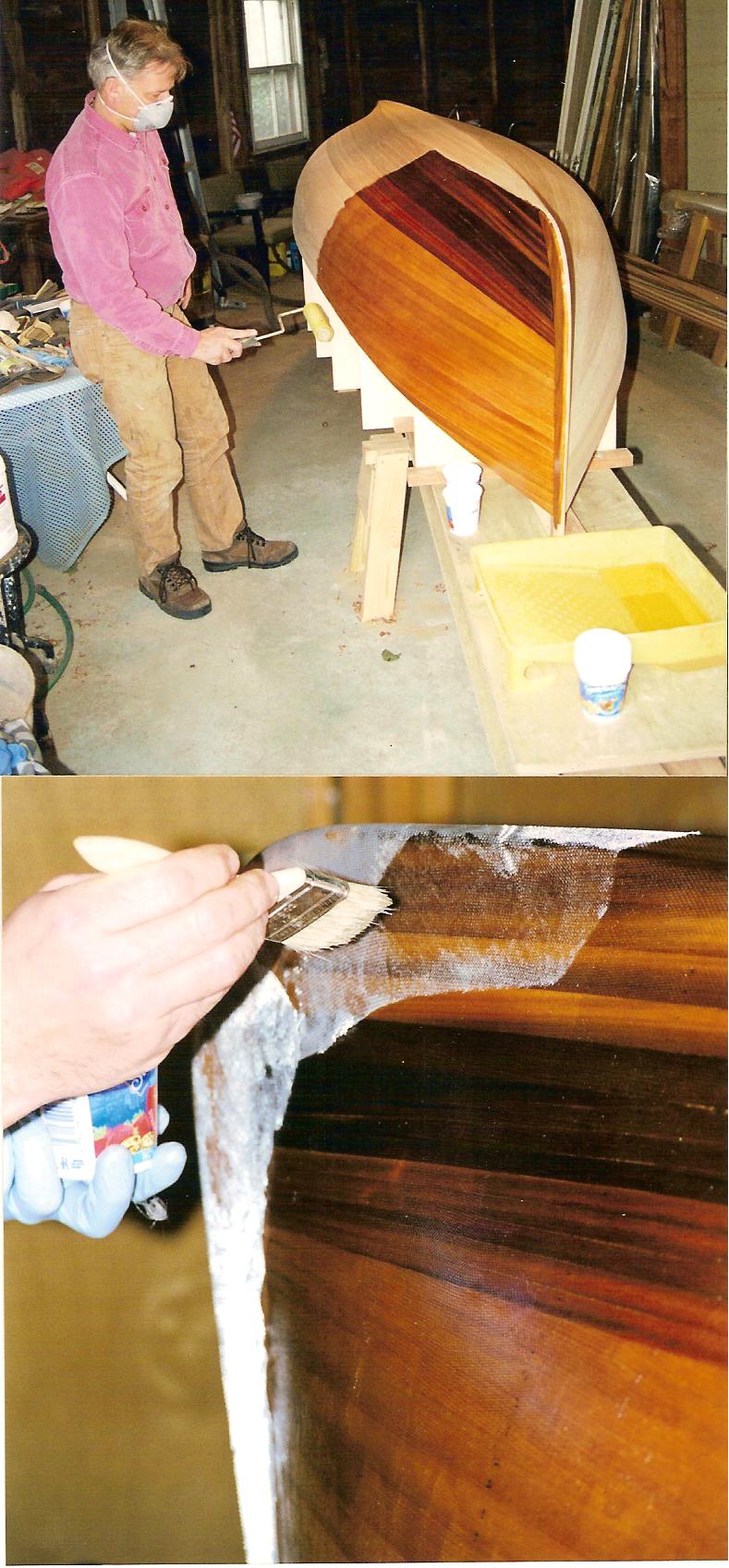

Epoxy resin is coated on the hull and then the fiberglass fabric is added.

The outside of the hull is done, with the fiberglass and epoxy rendered invisible.

Then the inside gets the same treatment.

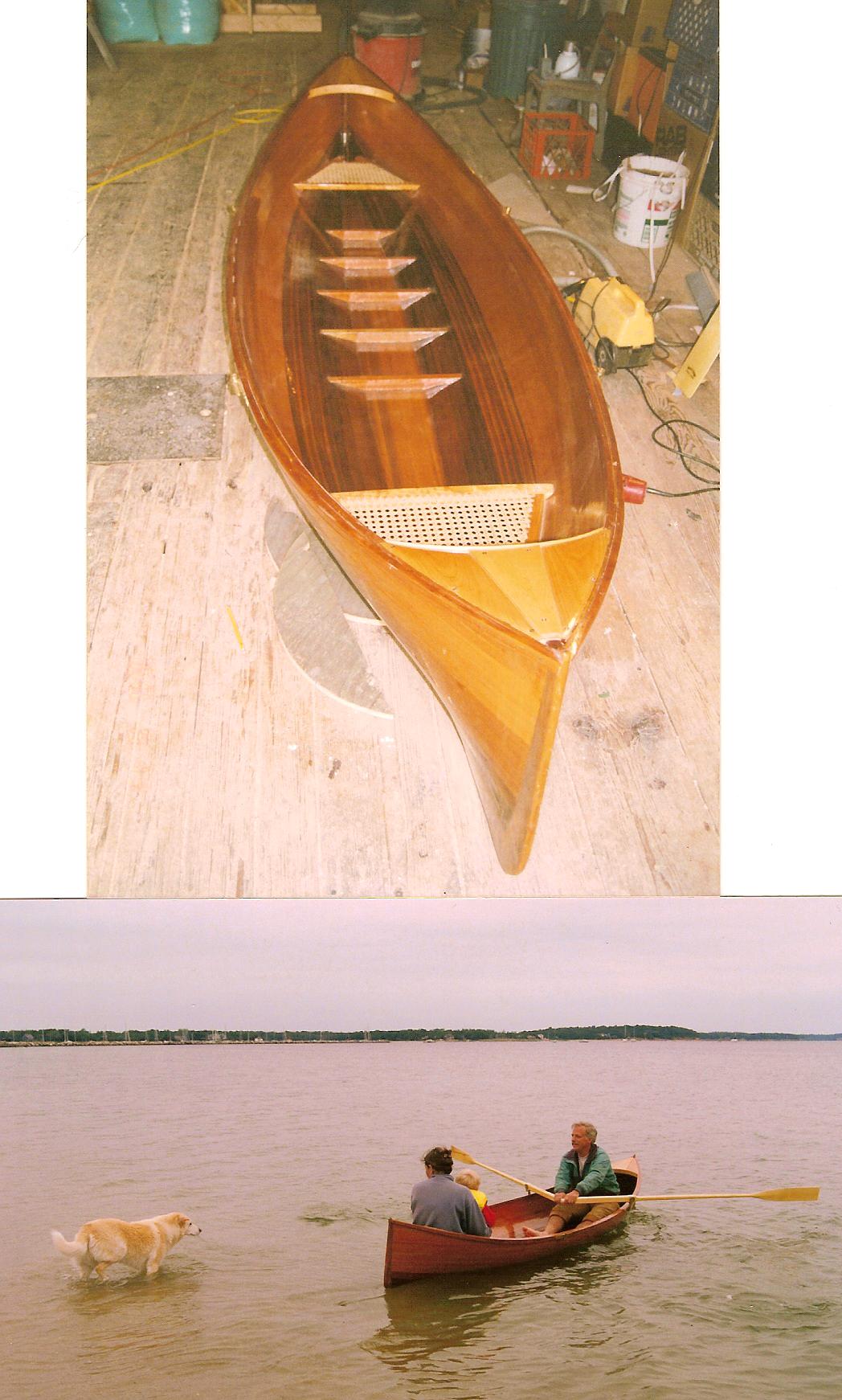

Gunwhales, decks and seats are inserted.

Floor timbers add strength.

The resulting water craft is fast, light and strong, and can bear weight. It is rowed like a row boat with the oars pinned to the gunwhales.